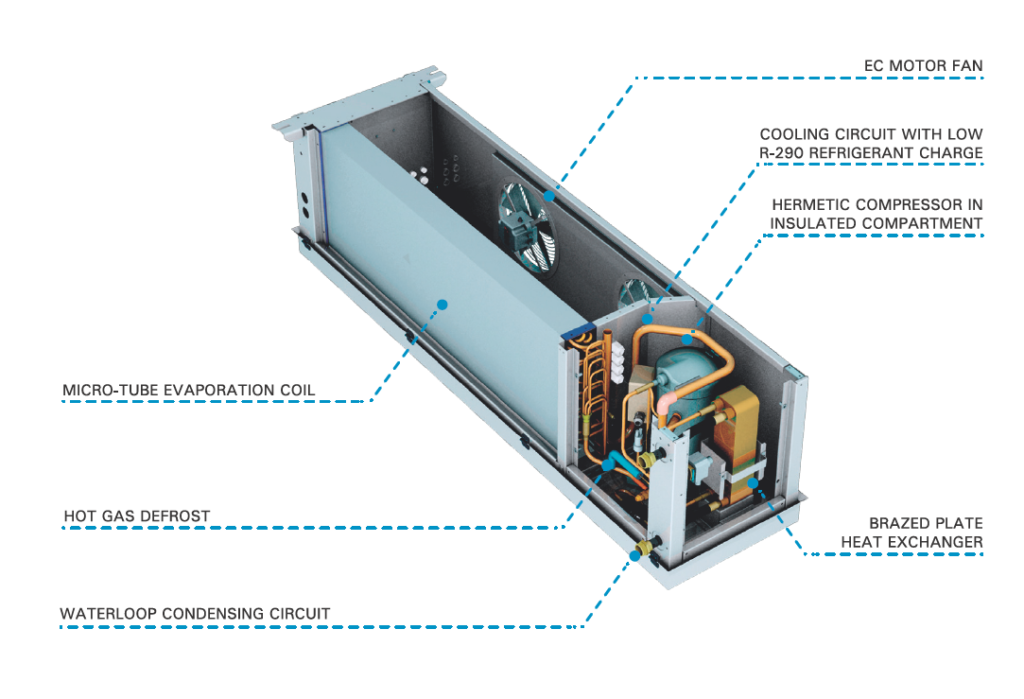

The waterloop refrigeration technology is based on a commercial and industrial water loop refrigeration system. The waterloop system consists of a series of DX cooling units distributed, with indirect condensation by a water circuit. On the other hand, one or more air-cooling units in parallel for condensation heat dissipation.

This system consists of:

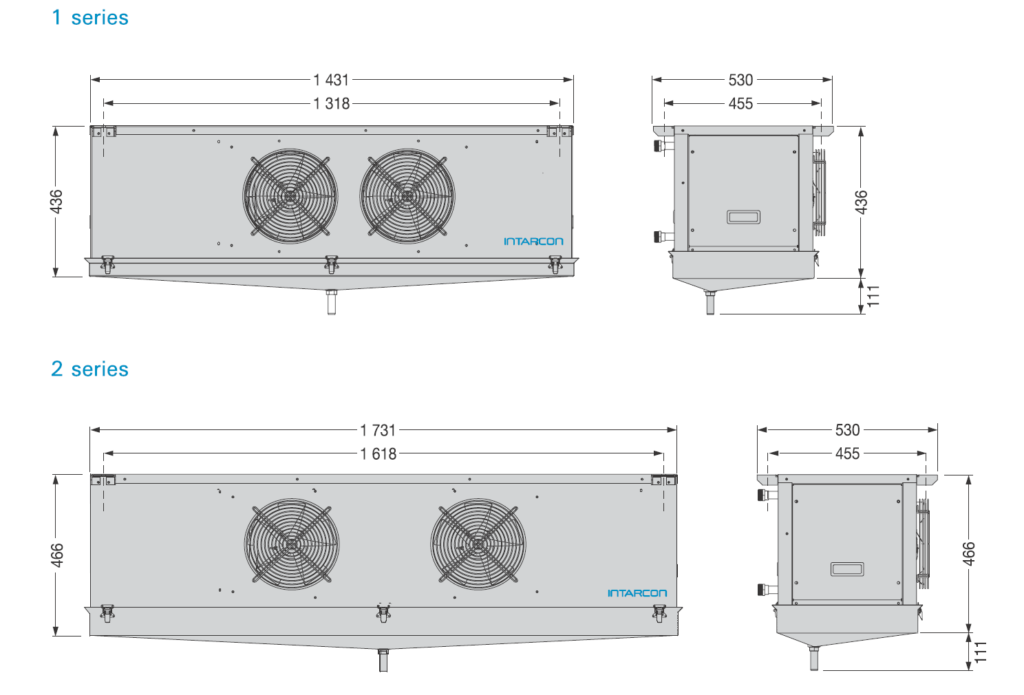

- Compact evaporator units with built-in compressor for medium or low temperature chambers.

- Refrigeration units designed for refrigeration of showcases and refrigerated displays.

- Air condensers with built-in hydraulic unit and temperature control.

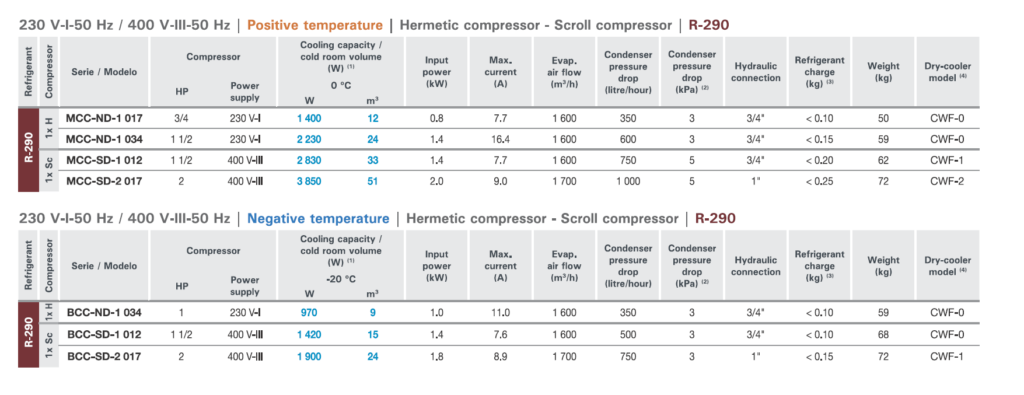

However, this system is characterized by the use of compact evaporator units with refrigerant R290. These are compact evaporator units with compressor, a new, efficient and sustainable alternative.

Waterloop evaporators units with compressor are compact units for installation inside small cold rooms, designed with natural refrigerant R290 and waterloop condensed.

- Compact unit condensed by water

- Minimal R290 refrigerant charge

- Easy and safe installation with connection to the condensation water circuit

COMPACT R290 SYSTEM

The waterloop evaporator units are hermetically sealed compact systems with a minimum charge of R290, exempt from the application EN 378.

They have a minimum R290 refrigerant change lower than the practical limit of the refrigerated volume.

ELECTRICAL BOARD

Electrical power and control board for outside installation.

- MCB protection of compressor and maneuver

- Electronic control with temperature control and recording of maximum and minimum temperatures

- Jet Cool function

- Energy saving function

- Optional air condenser management with waterloop temperature control and frost protection.