- Natural refrigerant

- Semi-hermetic reciprocating compressors

- Inverter driven compressors

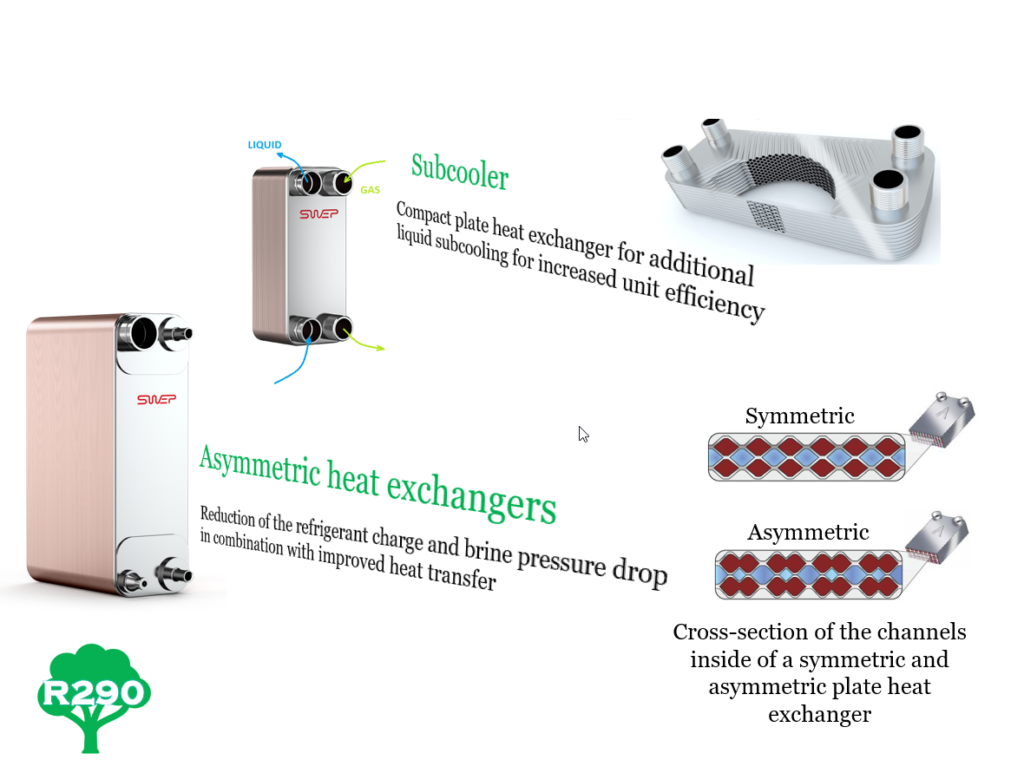

- High efficiency asymmetric evaporators and condensers

- Electronic expansion valve

- Innovative technical cooling solution for high energy efficiency

- R600a – for high temperature hot water applications

WATER COOLED CHILLERS

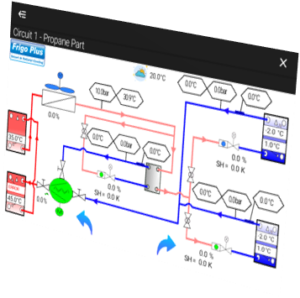

Water cooled chillers are used for indirect cooling for air conditioning of buildings, industrial processes, logistics centers for food retail, precision cooling of data centers. Heat transfer fluid can be water, mixture of water and ethylene/propylene glycol or some other secondary heat transfer fluid. Refrigerant is propane (R290), which due to its excellent thermodynamic properties allows the use of the chiller in the temperature range from -35 to 20 °C.

HIGH TEMPERATURE HEAT PUMPS

Isobutane (R600a) refrigerant enables very high temperature applications (up to 90°C) for this type of units. High temperature heat pumps are very suitable for peak loads of district heating systems and for heating of the buildings, also for industrial processes where waste heat must be raised to higher energy levels. If temperatures that need to be reached for heating are lower it is recommended to use propane (R290) water – water heat pumps for better efficiency and smaller footprint.

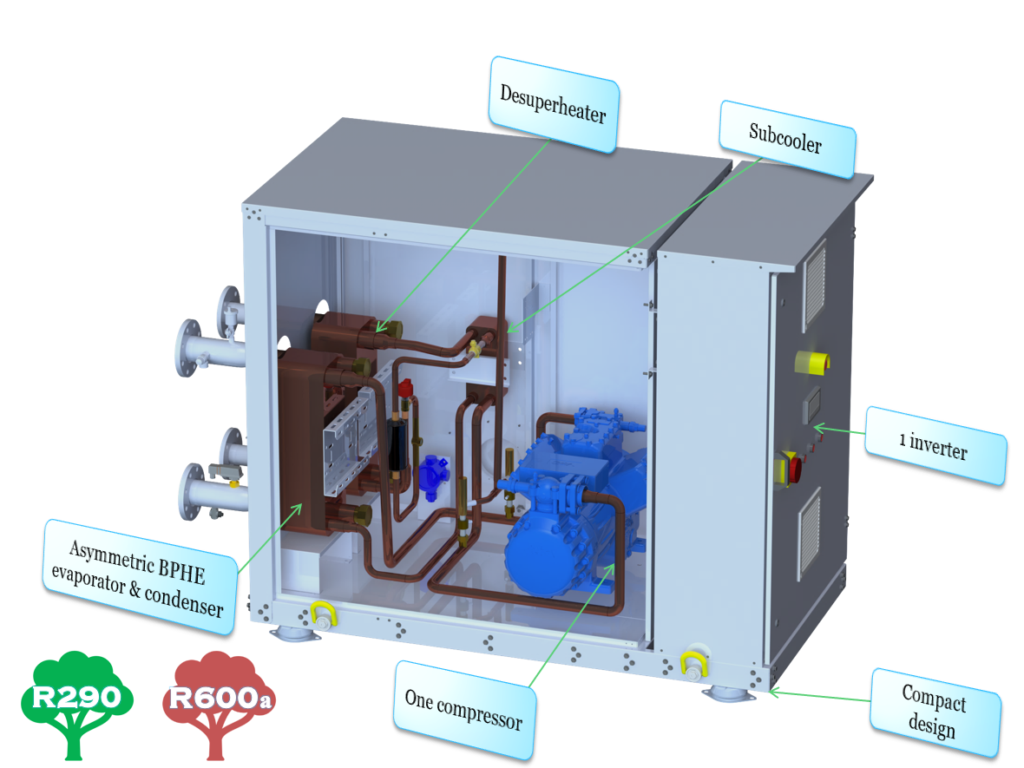

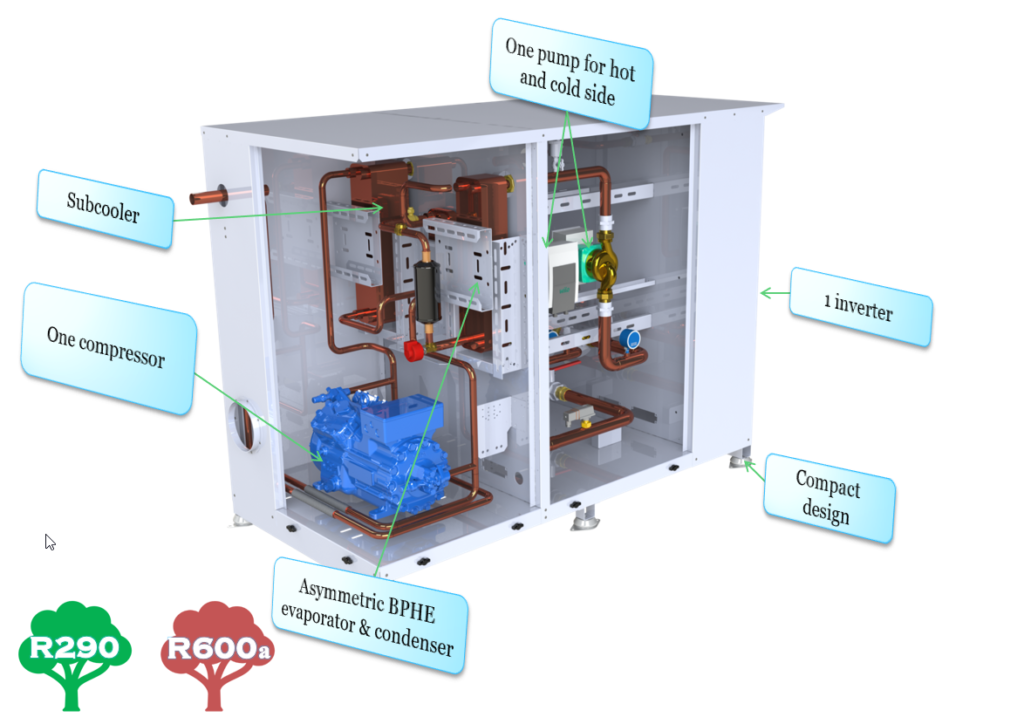

- Wone & MiniWone units are packaged in compact housing and all of the components of the refrigerant circuits are built into the unit.

- Units can easily be stacked (great flexibility of the capacity)

- Small footprint ensures that units can be installed in every machine room (up to 1100 mm unit width).

- Units can be made for outside installation.

- A microprocessor controls the operation of the unit in combination with optimized parameters in order to achieve as higher efficiency.

- Frigo Plus designed special hydromodules which fit perfectly with Wone & MiniWone chiller dimensions for confined machine rooms. Hydro modules can have buffer tank / hydraulic switch up to 800 L in combination with single or parallel primary or secondary pumps

HOUSING

- Housing made of powder-coated galvanized sheet metal

- Screws, nuts and rivets made of stainless steel

- Guard grille at the outlet from the axial fan

- Panels on compressor and hydraulic space with locks

ELECTRICAL PART

- Emergency stop mushroom pushbutton with CES key

- Phase failure monitoring relay

- Electrical cables labeling in the unit according to the electrical scheme

- Electrical cables for outdoor installation UV resistant

- Time relay for automatic reset of chiller in case of power failure

- Main switch on the electrical cabinet

- Cable clamp rail for power supply cable

- Control transformer 230/230 V and transformer housing earthing

REFRIGERATION CIRCUIT COMPONENTS

- Compressor with 2 rotalock valves, oil crankshaft heater, oil control glass

- Motor windings thermally protection and electronic module

- HP pressure switch is connected to the compressor before the rotalock valve

- Vibraflex for compressors with 2 or 4 cylinders

- Check valve in the discharge pipe

- Service ball valve before filter drier, filter drier and sight glass

- Service Schrader valve on LP and HP side

- Suction separator with integrated liquid coil for compressor safety and efficiency increase of the refrigeration circuit

- Thermal insulation of the refrigeration circuit low pressure side

- Safety valve on HP and LP side

- Electronic expansion valve with safety function of excessively high evaporation pressure

HYDRAULIC CIRCUIT COMPONENTS

- Flanged connection made of stainless steel

- Connections outside of the housing for easier connection to the system

- Automatic air vent valve mounted on the highest points of brine circuits

- Drain valves on lowest positions

- Safety valve 6 or 10 bar

- Standard thermal insulation of 19 mm

- Optional Y-strainer installed on the inlet pipe

- Optional AC/EC Primary pump *

- Manometer 0 – 10 bar (standard equipment with pump)

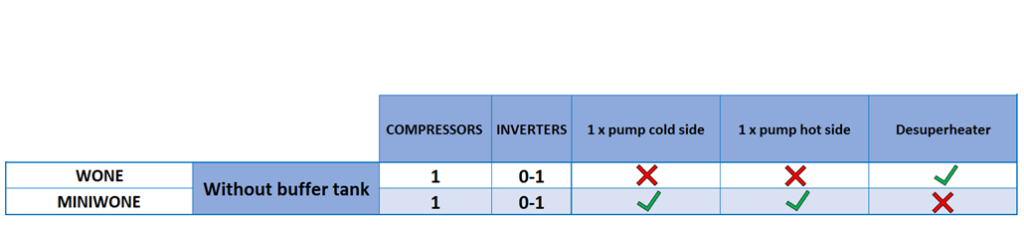

- Optional desuperheater**

*only available for MINIWONE

**only available for WONE

SAFETY

All chillers are designed in accordance with the highest safety standards and follows NORM EN378 for refrigerants from group A3.

ECOLOGY

Natural refrigerant: propane – R290.

It belongs to the group of hydrocarbons with GWP = 3 which is completely

exempted from the restrictions prescribed by the EU F-gas directive.

ENERGY EFFICENCY

Thanks to the ideal thermodynamic characteristics of the R290 refrigerant, and the optimal selection of the key components of the refrigeration circuit, the chillers have high energy efficiency and meet the requirements of ECODESIGN REGULATIONS.

QUALITY PROGRAM

- Testing units according to HRN EN 14511

- ISO 9001:2015

- Modul A2 – Monitoring of Final Assessment according to directive 2014/68/EU